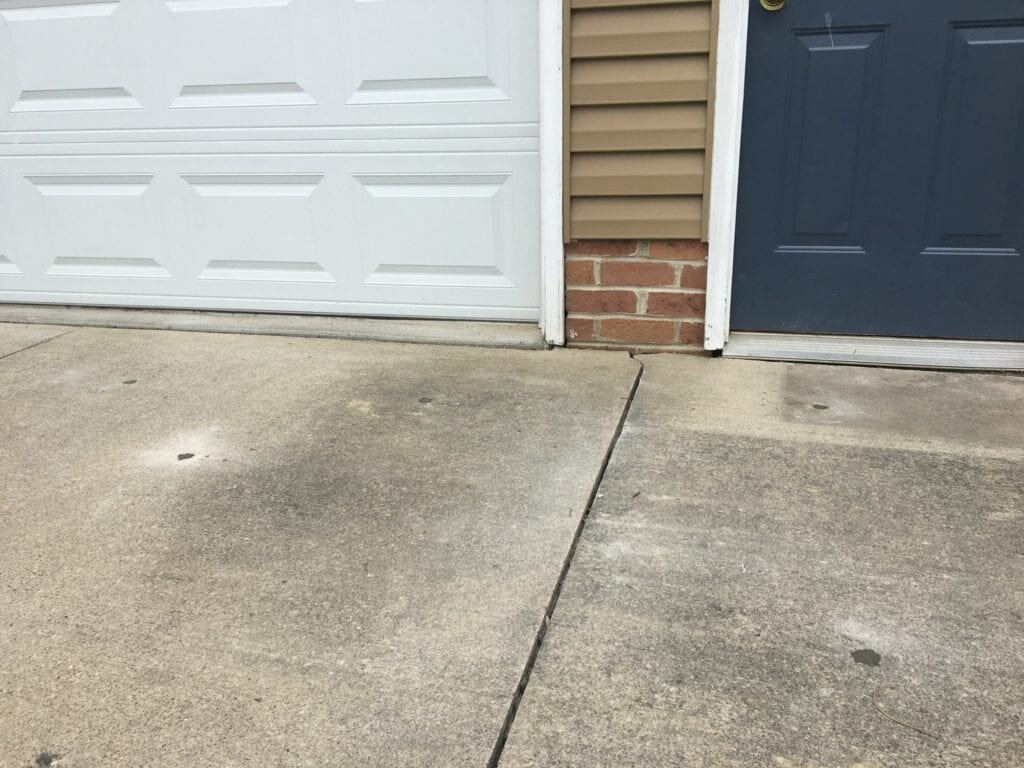

Driveway Leveling

Having an uneven driveway is not only an ugly sight, but it can also lower the value of your home and add additional strain on your car’s suspension system. We can help level your uneven or sunken driveways using our high quality polyurethane method of treatment. Unlike the common mudjacking process, high-density polyurethane has a quick dry time, it won’t move or sink, and can be driven on immediately.

Our proven method lifts concrete longer and is less invasive. This easy driveway leveling solution is the better and less expensive alternative to tearing out a driveway and will last for years to come.

Sidewalk Leveling

Keeping a sidewalk level and intact conserves the appearance of your home or business and prevents injuries and falls. Concrete is one of the most durable materials around, however exposure to the elements will deteriorate it over time. The main cause of uneven sidewalk is water, and with the proper technique we use to seal and caulk the cracks in your sidewalk, it will allow for longevity and reduce the amount of water that gets trapped in the sidewalk.

Our proven method of leveling sidewalks is not affected by water, does not change its shape or form, and will not break down over time as other materials often do.

Pool Deck Leveling

As the years go by, pool decks can become cracked and sunken, which causes a safety hazard. Our team uses a high quality polyurethane injection process to level out the pool deck and create a safe environment for families to enjoy pool time.

With our polyurethane injection process, very little of your pool deck will be disrupted. This quick and simple method of drilling small holes in concrete slabs, placing a hose underneath and then pumping specially formulated polyurethane foam into the debilitated soil will spread throughout the space and fill all holes and even the smallest of cracks.The result is a sound and strong foundation lasting for years to come.

Patio Leveling

Uneven patios can cause major problems for homeowners as they can lead to cracked concrete, poor drainage, sinking and falls and injuries. Besides being a safety hazard, they’re also an eye sore. Level Best uses a polyurethane foam method to rectify uneven patios that lifts concrete longer and is not invasive.

Slab Floors

As concrete floor settles, it can create damage to your home or business. When slab floors become jagged and irregular, it’s time for a repair. Our premier method for correcting slab floors is using a polyurethane injection process that fills holes in the soil underneath and raises slab floors to the right level.

Steps

Concrete steps can become uneven over time and dangerous for anyone to walk on. Our goal is to make sure your steps are completely safe, with all cracks filled and able to withstand the tests of time. Using our proven polyurethane injection process, it will lift concrete steps and allow them to be level and uniform.

Joint Stabilization

Joint Stabilization is a fast, cost-effective and efficient fix for loose, or rocking joints and cracks in concrete floors. This services is designed to eliminate damage and restore smooth, positive load transfer at all joints and cracks permanently.

Joint integrity can make an enormous difference in preventing accidents and business disruption as well as prolong the life of your building or warehouse. Click below for a free estimate on joint stabilization services.

Garage & Basement Floor Leveling

Sunken garage and basement floors aren’t a great sight and can cause water drainage problems. With the loss of space, the functionality of the room diminishes. Our professional team lifts uneven flooring and in just a few days you can get your space back.

Our high density polyurethane injection process allows us to raise sunken floors with minimal invasion and a polished finish.